Environmental Activities

MJC Group recognizes the importance of corporate responsibility when it comes to protecting the planet, which is why we are continuously taking part in environmental activities such as reducing resource and energy consumption, reducing waste, advancing recycling processes, and ensuring appropriate management of chemicals.

- Energy Usage

- Appropriate Management of Chemicals

- Water Resources

- Wastewater Treatment Equipment

- Introduction of Renewable Energy

- Energy Conservation Efforts

- Initiatives for Reducing Environmental Impact

Energy Usage

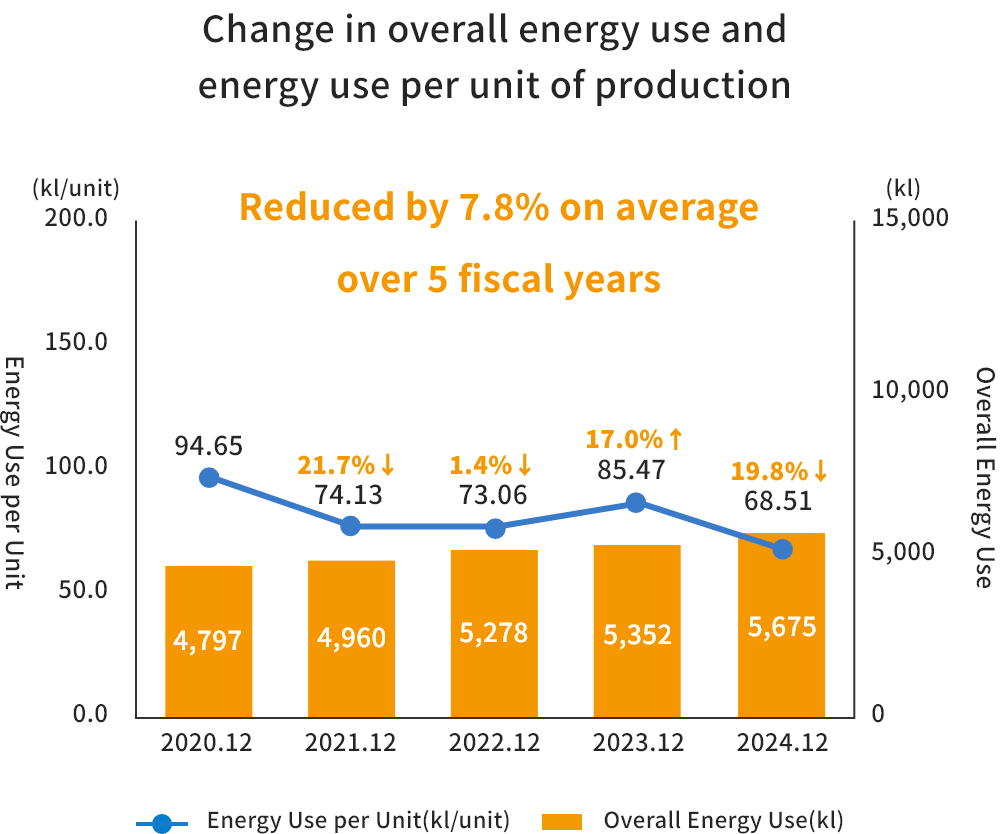

MJC monitors the energy usage of all domestic business locations and actively works to reduce energy consumption per unit.*¹

The increase in energy usage in 2024 is attributed to the increased operation of production and air conditioning equipment, as well as the commencement of energy supply to the new building at the Aomori Factory starting in October.

Compared to the previous year, the energy consumption per unit decreased by 19.8%, and over the five-year period from 2020 to 2024, we achieved an average reduction of 7.8%.

We will continue to promote the reduction of energy consumption per unit as a measure to prevent global warming, and we will also work on energy conservation.

*¹: Energy Consumption Per Unit: A value that indicates energy efficiency. The smaller this value, the higher the production efficiency, which signifies energy conservation and contributes to the prevention of global warming (MJC's unit is calculated based on energy usage and production numbers).

| CY2020 | CY2021 | CY2022 | CY2023 | CY2024 | |

|---|---|---|---|---|---|

| Energy Usage (kl) |

4,797 | 4,960 | 5,278 | 5,352 | 5,675 |

| Energy Consumption Per Unit (kl/unit) |

94.65 | 74.13 | 73.06 | 85.47 | 68.51 |

|

Average yearly change rate in energy consumption per unit (2020-2024) *² |

|---|

| -7.8% |

*²: Average yearly change rate in energy consumption per unit: Figure shown represents change based on usage figures of any given calendar year compared to the preceding calendar year where it is set at 100%.

Appropriate Management of Chemicals

Chemical materials that MJC uses are fully managed in accordance with all relevant regulations.

Before the introduction of any chemical material, risk assessments are performed to evaluate levels of possible danger to human health and in turn to take measures to deal with such risks, if necessary.

In addition, we have set up a chemicals registration system, allowing us to manage the quantity of any given chemical being used and apply the appropriate regulations according to each division. This is MJC's compliance evaluation procedure to ensure the appropriate management of chemical materials used.

Water Resources

MJC Group is committed to reducing water usage based on our integrated management policy.

Water Usage

| Scope | CY2022 | CY2023 | CY2024 |

|---|---|---|---|

| Domestic Total | 114 | 111 | 134 |

| Overseas Total | 10 | 10 | 11 |

| Total | 124 | 121 | 145 |

| * The overseas usage includes the totals for the production factories, MEK Co., Ltd., Taiwan MJC Co., Ltd., and MJC Microelectronics(Kunshan)Co., Ltd. | |||

The Group uses over 90% of our water resources at domestic sites, and all of it is municipal water.

Aomori Factory Water Usage Performance (January to December)

| CY2020 | CY2021 | CY2022 | CY2023 | CY2024 | |

|---|---|---|---|---|---|

| Municipal Water | 72 | 94 | 105 | 103 | 125 |

| Other | 0 | 0 | 0 | 0 | 0 |

Efforts to Reduce Water Usage

At the Aomori Factory, which uses the most water, we have undertaken efforts to reduce water usage. Starting in April 2024, we shortened the blow-off time of the pure water heat exchanger cooling, and beginning in May, we implemented process improvements to shorten the product washing time. As a result, we were able to reduce water usage by 37 m³ per day. This initiative led to an estimated annual reduction of 9,450 m³ of water usage in 2024.

Volume of Effluents

| Scope | CY2022 | CY2023 | CY2024 |

|---|---|---|---|

| Domestic Total | 101 | 98 | 114 |

| Overseas Total | 10 | 10 | 11 |

| Total | 111 | 108 | 125 |

| * The overseas discharge volume is the total of the production factories, MEK Co., Ltd., Taiwan MJC Co., Ltd., and MJC Microelectronics(Kunshan)Co., Ltd. | |||

Aomori Factory Volume of Effluents (January to December)

| CY2020 | CY2021 | CY2022 | CY2023 | CY2024 | |

|---|---|---|---|---|---|

| Sewage | 59 | 82 | 92 | 90 | 105 |

Wastewater Treatment Equipment

At the Aomori Factory of MJC, to ensure that wastewater discharged from the manufacturing process does not burden the environment, we have introduced wastewater treatment equipment. The treated water undergoes processes such as coagulation sedimentation before being discharged into the sewage system.

Additionally, since precious metals like gold are used in the production of probe cards, we recover and recycle these metals from the wastewater.

Introduction of Renewable Energy

To contribute to a decarbonized society, MJC Group began the introduction of renewable energy in 2024 and is working on the gradual reduction of GHG emissions (Scope 1+2) at our main domestic production sites.

Energy Conservation Efforts

Conversion to LED Lighting

As part of our energy conservation efforts, we are progressing with the replacement of lighting fixtures at our domestic sites with LED lighting, and MJC has completed over 90% of the replacements. This has significantly reduced power consumption compared to conventional lighting, and has also contributed to the reduction of CO2 emissions.

Initiatives for Reducing Environmental Impact

Green Purchasing

MJC promotes "green purchasing" to reduce environmental impact when purchasing products.

Since 2018, we have been using the environmentally friendly material "LIMEX" for our business cards.

"LIMEX" is a new material from Japan primarily made of limestone, and compared to regular paper business cards, it can save approximately 10 liters of water per box (100 cards).

Because it is produced with minimal use of water and wood, it contributes to the conservation of forest and water resources.

※"LIMEX" is a registered trademark of TBM Co., Ltd.

Environmentally Friendly Printing

MJC is striving to minimize printing by switching to digital catalogs. For catalogs and booklets that still require printing, we use environmentally friendly FSC-certified paper,* contributing to forest conservation and sustainable resource use.

Additionally, we use vegetable oil ink derived from plants and recycled oils for printing, further reducing environmental impact.

* FSC-certified paper: Paper produced using wood from responsibly managed forests.